Ammonium nitrate in the production process for three pressurized and boiling granulation method without evaporation

When the starting material of more than 58% concentration of nitric acid , and the use of high pressure in the reactor , the concentration of the solution after the reaction has reached a very high level , which can not completely evaporated system using fluidized bed granulation method , in place of tall granulation tower to make the process much simpler .

This process is characterized by :

1 , and in the process

After sufficient pressure gas ammonia and nitric acid in the respective heat exchanger fully preheated , continuously and in a special reactor . Reaction of ammonia gas and nitric acid plus heat released into the preheated raw heat , enough to evaporate all the water with dilute nitric acid into the . The reaction pressurized to prevent evaporation of nitric acid , nitric acid , especially when heated , but also reduces the loss of nitrogen in the gas phase is fixed . Since ammonia gas preheating, and in the process of turbulence increases, while the ammonia gas is heated to the maximum possible temperature 200 ℃, not only improve the concentration of the melt , and made a strong mixing condition of the reaction medium , but also improve the operating system, reduce production losses.

Ammonia gas liquid separation of the emulsion formed in the reactor and , in the first 3 to 3.5 kg / 2 cm in from the new separator for , and then under vacuum conditions of 600 mm Hg in a vacuum for the evaporator . Evaporation under pressure steam separated accounts for 90 to 95 % of the total . This higher gas parameters , it is reasonable to recover heat for other aspects . Evaporated in vacuo , water is evaporated from the melt itself to reduce the temperature of the melt , and the concentration can be increased to 99.5% .

2 , fluidized granulation method of ammonium nitrate

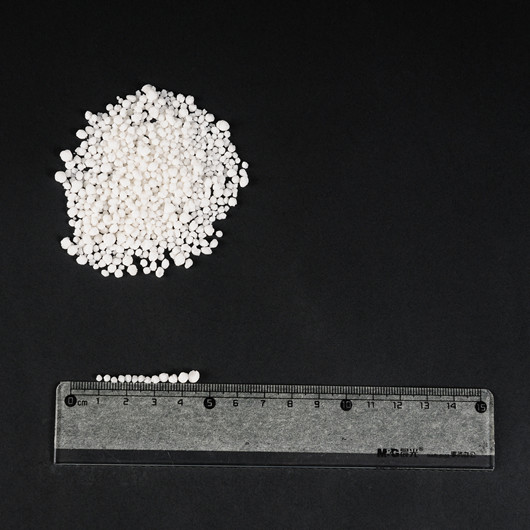

In a fluidized bed of ammonium nitrate melt crystallization and granulated ammonium nitrate , and sulfate . Compared with a granulation of the tower , the device volume by 18 to 25 times the intensity , the product of hard particles , the temperature is low , greatly reducing the caking of the product . However, its power consumption is large.

The 95% ammonium nitrate solution through a nozzle in a fluidized bed or the upper side injection , into a certain amount of pressure from the bed drum air , so in the bed into a mist of spray droplets immediately dried crystals of ammonium nitrate into a solid , thereby forming a solid fluidization . As time increases , the particle growth of 2 to 3 mm, the temperature drops , remove the product from the bed position. Into the air within the bed , out of the upper part of the device , dust recovery after discharge .

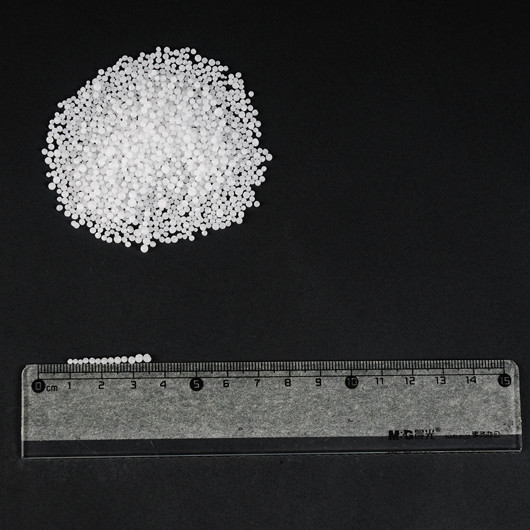

3 , pan granulation method ammonium nitrate

The melt of ammonium nitrate in the can through the nozzle exit speed of the tilting disc , mist droplets crystal grains i.e. , the rotation of the disk , the particles also showed motion. After an appropriate time staying materials , particle growing up, and then continuously discharged 2 to 4 mm as a finished product . Ventilation and cooling crystallization can strengthen the process if necessary.

Particle size on the speed of the disk , increasing the speed of particles smaller ; plate tilt angle decreases , the particles residence time in the tray , the particles increases. Can be adjusted according to product requirements.