The processes involved in the production of ammonium nitrate in industry, although chemically simple, are technologically challenging. The acid-base reaction of ammonia with nitric acid gives a solution of ammonium nitrate:

HNO3(aq) + NH3(g) → NH4NO3(aq)

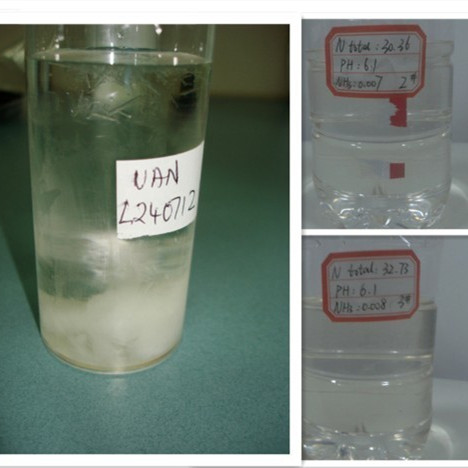

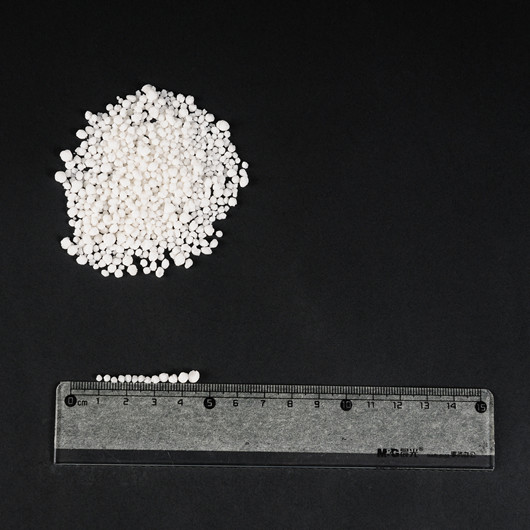

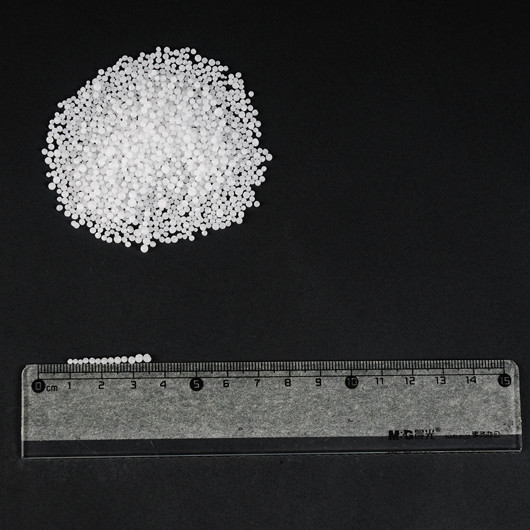

For industrial production, this is done using anhydrous ammonia gas and concentrated nitric acid. This reaction is violent and very exothermic. After the solution is formed, typically at about 83% concentration, the excess water is evaporated to an ammonium nitrate (AN) content of 95% to 99.9% concentration (AN melt), depending on grade. The AN melt is then made into "prills" or small beads in a spray tower, or into granules by spraying and tumbling in a rotating drum. The prills or granules may be further dried, cooled, and then coated to prevent caking. These prills or granules are the typical AN products in commerce.

The Haber process combines nitrogen and hydrogen to produce ammonia, part of which can be oxidized to nitric acid and combined with the remaining ammonia to produce the nitrate. Another production method is used in the so-called Odda process.

Ammonium nitrate is also manufactured by amateur explosive enthusiasts by metathesis reactions:

(NH4)2SO4 + 2 NaNO3 → Na2SO4 + 2 NH4NO3

Ca(NO3)2 + (NH4)2SO4 → 2 NH4NO3 + CaSO4

Sodium sulfate is removed by lowering the temperature of the mixture. Since sodium sulfate is much less water-soluble than ammonium nitrate, it precipitates, and may be filtered off. For the reaction with calcium nitrate, the calcium sulfate generated is quite insoluble, even at room temperature.