First, the principle of crystallization

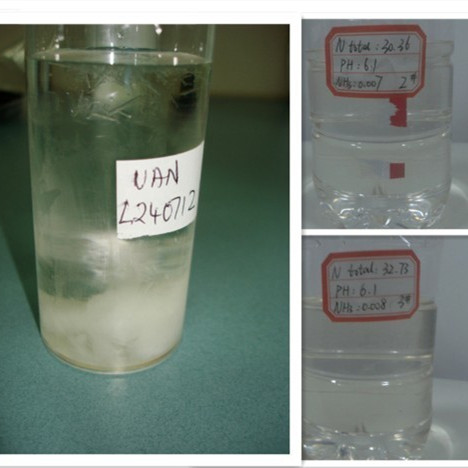

Ammonium nitrate crystals were precipitated from the aqueous solution during the crystallization process is called .

Any solid material in contact with the solution , such a solution is not saturated , then the solid was dissolved ; passed as a solution is saturated, the substance remaining in the solution will precipitate a crystal portion sooner , but just saturated solution , the solid was dissolved ; such saturated solution has passed , the remaining material in the solution to precipitate a crystal portion will sooner or later , but just saturated solution , then the precipitated crystalline solid was dissolved with an equal number of sides , with the result that neither dissolve nor crystallization, At this point its already solid balance each other. Bath crystalline solid solute , you must first make the solution was too saturated , ie destroy equilibrium .

Equilibrium relationship between solid and its solution can usually be solid solubility in a solvent represented . Solubility and chemical properties of substances , related to the nature and temperature of the solvent . Certain substances in certain Solubility mainly varies with temperature . As a saturated solution of ammonium nitrate at 100 ℃ was 92 %, and 60 ℃, 82% saturated solution .

According to the relationship between the temperature and the solubility of ammonium nitrate , can effectively guide the crystallization operation in : adiabatic vacuum evaporation , reducing the temperature of the ammonium nitrate solution , a corresponding increase in the concentration of ammonium nitrate solution so as to achieve a supersaturated solution of ammonium nitrate , wherein the air excess water of the back to go, so equilibrium damage to precipitate crystals.

In the crystallization process for vacuum insulation, vacuum evaporation and crystallization can be divided into two processes . The ammonium nitrate solution was relying on heat and heat of crystallization , wherein the negative pressure in the evaporation of water , the solution reached saturation concentration is increased , then the crystallization procedure.

For example : 1000 kg of finished processing nitrate concentration of 92% , heat and heat of crystallization temperature was 109 ℃ when the crystallinity degree of vacuum of over 15% was evaporated in vacuo , the water can evaporate about 120 kg of ammonium nitrate finished 0,5 % or less of water .

Simultaneously, the sensible heat and heat of crystallization of the ammonium nitrate is consumed in the heat of vaporization of water , its temperature drops to below the freezing point of the thermal crystallization to achieve the purpose .

Factors affect the crystallization process 1.

( A ) dissolving the ammonium nitrate concentration and temperature . Concentration increased, the evaporation process load reduction , reduce water evaporation , crystallization faster ; temperature increased, increase the heat into the crystallizer is conducive evaporation, crystallization and thus will speed up the process .

( 2 ) increase the degree of vacuum , be conducive to crystallization , to improve the degree of vacuum to reduce the boiling point of the solution of ammonium nitrate , water vaporization speed, the supersaturated solution temperature is reduced , increasing the cooling intensity , speed up the crystallization process , the equipment efficiency. Ammonium nitrate is exothermic crystallization process , the heat released in the finished product after crystallization temperature, the crystallization temperature is high when the finished release less heat , the heat release is low temperature polycrystalline finished , there is a difference since the crystalline transition of heat.

( 3 ) stirring speed . Appropriate stirring , the crystallization process is conducive to heat transfer effects , the equipment efficiency. However, the stirring speed is too fast , so that the latter is easy to produce large amounts of crystalline powder, which is pumped lost , but the stirring speed is too slow , poor heat transfer process within the device , evaporation intensity decreased, so that the finished product is also reduced to form chunks intensity factors of production . Crystalline solid with stirring to prevent sticking to the crystallization apparatus , and to the discharge of the finished product .

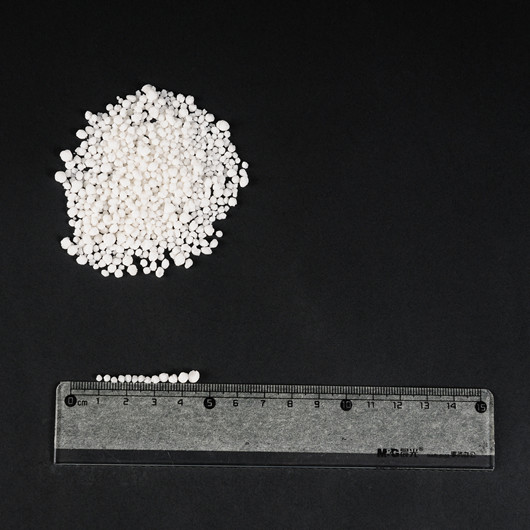

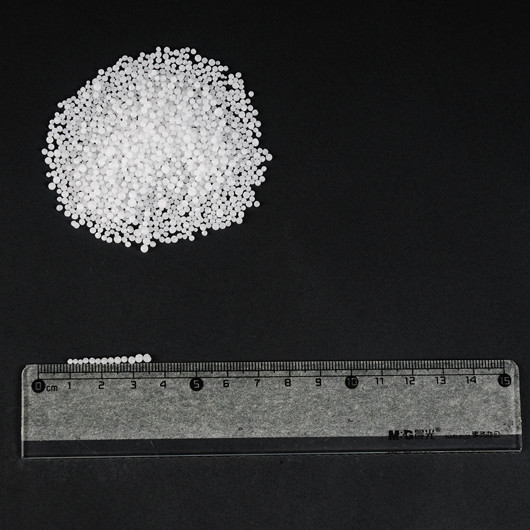

( 4 ) crystallization time , crystallization time is appropriately increased , the material can be fully evaporated in the apparatus to be properly stirred to a uniform grain size of ammonium nitrate and water to reduce the material temperature is lowered. No side product was a large part of the block, is not conducive to packaging, the moisture content is also high . But excessive extension of time , the ammonium nitrate dust can cause a lot of damage. And the crystallization time is also an important indicator of the efficiency of production , generally in about 10 minutes crystallization process .

2 , crystallization method

Many types of equipment producing ammonium nitrate crystals , the crystals have a boat-shaped , tubular , and rotating the rotary mold cooling crystallizer . Due to the above equipment production capacity of small , inefficient , so in recent years , has been replaced by large capacity, high-efficiency vacuum crystallizer and large granulation tower. Continuous crystallization is currently being further developed , and also added to prevent caking additives.

If necessary, different methods may be employed ammonium nitrate crystals , in general , used as an agricultural fertilizer ammonium nitrate , preferably use is made of granular finished granulation tower , more convenient to use ; industrially used as a nitrate, vacuum crystallization mechanism can be stirred into segments like the end of the finished product. Some plants add fillers in the crystallization process , the formation of ammonium nitrate is more enhanced waterproof explosion effect. However, due to the higher price of granulation tower , at present , China's small ammonium nitrate plant , ammonium nitrate melt liquid crystals are generally used vacuum crystallizer . This pressure and our discussion , water-jet vacuum is carried Sec real hair , ammonium nitrate production process of crystallization , the crystallization is used vacuum crystallizer .