Ammonium nitrate production process for a period of two pressurized evaporation and granulation in

1 , and in the process : 6kg/cm2 ammonia from the ammonia gas into the lower part of the evaporator and control . 50 to 60 % nitric acid after the preheating and evaporation of steam , into the lower portion and the pump unit . Gas ammonia and nitric acid in the neutralizer rapid response, and to ensure the neutralizer solution produced a strong cycle. And the operating pressure of 3.5 to 4 kg / cm 2 , the reaction temperature 200 ℃, the top of the neutralization and evaporation steam is discharged into the evaporator as a heat source . The outlet and the concentration of the solution is 80 to 85% . After the neutralizer , after adjusting the pH of the solution flows into the tank .

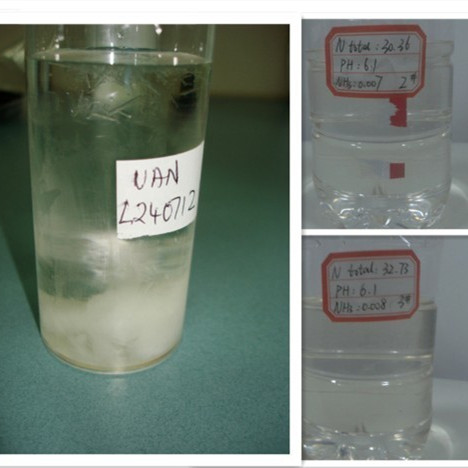

The solution was concentrated two procedures: Preparation of the ammonium nitrate solution and extraction process directly to the evaporator , an evaporator operating under vacuum , using water jet pump , the use of heat and evaporation of steam. After evaporation of the solution concentration up to 95 %. Evaporating the solution before and after the exchange , to prevent clogging of the concentrated solution crystallization .

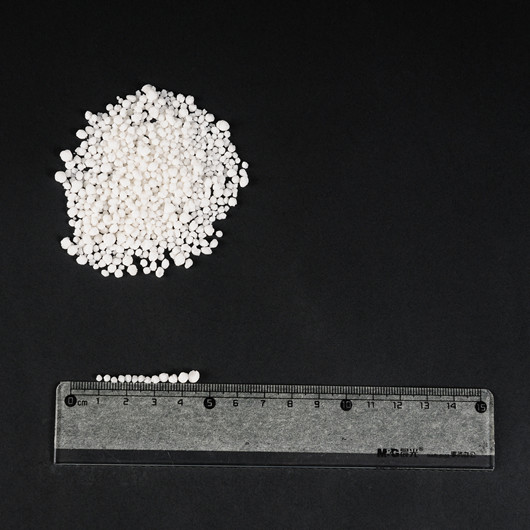

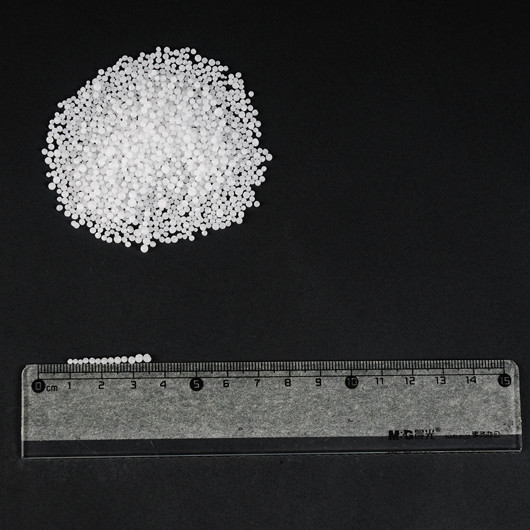

This process , when the concentration of nitric acid is 50% starting material , in addition to self- generated steam , 54-57 % when using nitric acid , ammonium nitrate to produce one ton of steam generated outside the self- addition of 1 to 1.6 tons is still unnecessary . Ammonium nitrate solution was concentrated and the home agent into the mix after Tim crystallized with stirring machine , after a preliminary concentrated and crystallized into the groove granulator , which has a special two reverse rotation of the blade to ensure that the materials and by the sieve return of the device strongly mixed powder , the final part of the water is evaporated into the grain , the process slurry material . Thus the material from the lower part into the rotary drum through the air dried hard particles forming the final crystallization . Materials are exported to the rotary drum screen means to separate the material between 2 to 4.5 mm as the finished product. Particles larger than 4.5 mm and less than 2 mm finely and return granulator crushing machine, as returned material used. Return amount is generally 2 to 3 times higher than the desirable finished .

Sifting qualified products into the second rotary barrel plus catch powder. Continuously fed by a metering catching powder feeding device . Initially cooled to a temperature higher than the atmospheric 10 ~ 15 ℃, this rotary cylinder with fresh air cooling.