Ammonium nitrate production methods in atmospheric and vacuum evaporation Sec evaporative crystallization of ammonium nitrate production

This method of producing ammonium nitrate plant for our small general approach .

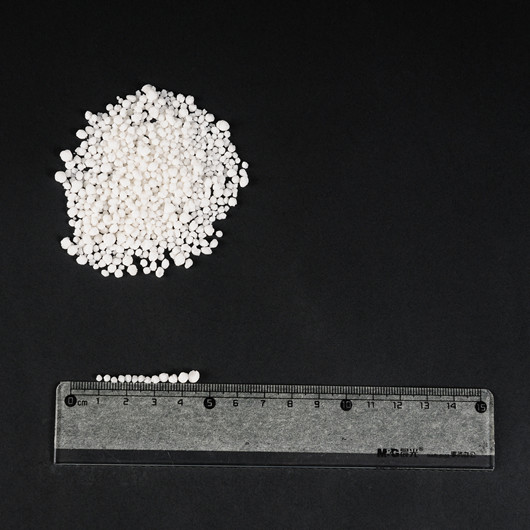

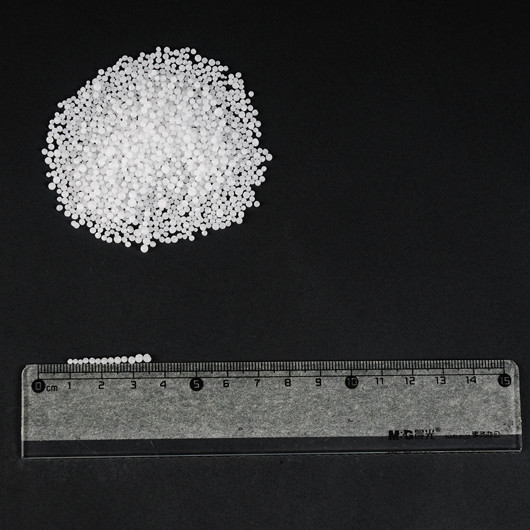

Ammonia gas delivered by the post of ammonia , ammonia filtered through the evaporator tube is preheated waste gas tube ( with ammonia and to prevent separation of oil ) , the adjusted measure , adding the lower middle and inner cylindrical shell , bubbling rise. Sent by the section nitrate stored in a tank of nitric acid nitric acid , nitric acid is pumped from the high slot . And in regulating the flow through the inner tube into the upper portion of the spray , the ammonia was bubbled countercurrent contact with a lower rise and the reaction carried out in a dilute ammonium nitrate solution from the upper part of the inner cylinder to the outer cylinder of the anti- downstream from the bottom into three casing liquid seal , the first line up , then down, and finally up to the upper part of the small separator into the outer . The separated gas to the separator, ammonium nitrate solution from the lower part of the small separator into another neutralizer , supplemented plus some ammonia gas ammonium nitrate solution was slightly acidic . Under the action of vacuum , the ammonium nitrate solution into the evaporator tube within the uplink period is outside of the steam pipe is heated to evaporate part of the water , to the separation section of the separator , a solution of ammonium nitrate over a period of lower feed tube downstream from the lower part into the Sec evaporator tube upward, heated by steam heating tube and further evaporation of moisture contained by Sec separator separation , ammonium nitrate solution under Sec pipe downstream from the liquid through the tube into the solution tank seal . In the additional amount of liquid seal cylinder gas ammonia , the solution was slightly alkaline . Under the action of vacuum , from the ammonium nitrate solution was pumped into the crystallizer tank , and stirring under vacuum action , the solution contained in the water is sucked out substantially , ammonium nitrate crystals become finished , release the door from the pan crystallizer , dried belt conveyor to the packaging, weighing from small belt after delivery by sewing machine seam , finished with the car transported to the Treasury sold.

And out into the upper portion of the evaporator and steam ( steam and a secondary reaction ), and separated by the gas-liquid separator wherein the entrained droplets of ammonia gas derived from the top of the separator , in a tangential direction into the trap , trapping of ammonium nitrate droplets have come into the trap again and in the lower part , a trap for the upper section of the steam out of the evaporator heating , gas separators to separate .

Sec waste heat steam evaporator heating with nitric acid byproduct steam boilers , Sec waste heat out of steam after the ammonia solution tank insulation and then filtered through the evaporator to the bathhouse , Sinochem , office buildings , heating or send soft pool .

One , two sections separated by the separation and crystallization of machine exhaust steam evaporated water vapor , the water jet is mixed with water into the pool .

From the acid absorption tower cooling backwater ( residual pressure 6 kg / cm 2 ) adding water evaporation and crystallization ejector for vacuum use, while cooling effect . After the water condensate and noncondensable gas mixture to the pool , using some part of the cycle to drain .

This process is characterized by :

1 , the ammonia gas preheating using waste steam , acid tank plus recovery , recycling not only the synthesis gas in the gas tank of ammonia , its effect is less than other recovery method for recovering ammonia losses, and got a high temperature dilute ammonium nitrate was significantly in favor of the reaction process .

2 , evaporating steam heating and evaporation section with the steam , Sec byproduct waste heat boiler steam Zigeiyouyu nitric acid , so that the burden for reducing the production of ammonia vapor , but also make the system stable operation .

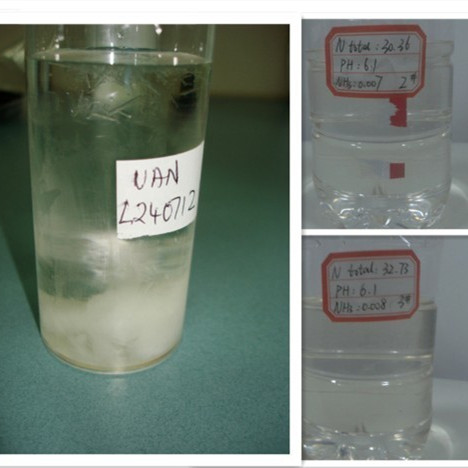

Under 3 Sec feeding tube into the solution tank using liquid seal drum intuitive cutting, can be directly observed concentration, pH and lower material and circumstances, always find problems ; timely adjustment to ensure normal production, while allowing sampling and analysis .

4 , the tube was sealed again in the bath and is added with a reflux tube , while driving , or can produce a dilute solution of ammonium nitrate is not normal , and then return to the device and then evaporated , the job which is not only easy to operate, and to ensure normal operation and product qualification rate of crystallization of positions to provide the conditions and eliminating the ammonium nitrate solution pump .

5 , the crystallization of intermittent operation , the fault is easy to rule out , has little effect on the upper and lower positions , and easy maintenance. The crystallization vacuum plus a buffer tank to accelerate the feed , triple crystallization ability .

6 , evaporate after Sec separator for the same degree of vacuum tubes alone , evaporation and crystallization using water jet , instead of mechanical vacuum pumps and air coolers. This greatly reduces the equipment , simplifying the process and facilitate the operation , convenient maintenance , improve efficiency , reduce consumption, reduce accidents, ensure the production . And generally small plant steam supply shortages, therefore , the use of water jet pump than with steam ejector easy.

This method of producing ammonium nitrate plant for our small general approach .

Ammonia gas delivered by the post of ammonia , ammonia filtered through the evaporator tube is preheated waste gas tube ( with ammonia and to prevent separation of oil ) , the adjusted measure , adding the lower middle and inner cylindrical shell , bubbling rise. Sent by the section nitrate stored in a tank of nitric acid nitric acid , nitric acid is pumped from the high slot . And in regulating the flow through the inner tube into the upper portion of the spray , the ammonia was bubbled countercurrent contact with a lower rise and the reaction carried out in a dilute ammonium nitrate solution from the upper part of the inner cylinder to the outer cylinder of the anti- downstream from the bottom into three casing liquid seal , the first line up , then down, and finally up to the upper part of the small separator into the outer . The separated gas to the separator, ammonium nitrate solution from the lower part of the small separator into another neutralizer , supplemented plus some ammonia gas ammonium nitrate solution was slightly acidic . Under the action of vacuum , the ammonium nitrate solution into the evaporator tube within the uplink period is outside of the steam pipe is heated to evaporate part of the water , to the separation section of the separator , a solution of ammonium nitrate over a period of lower feed tube downstream from the lower part into the Sec evaporator tube upward, heated by steam heating tube and further evaporation of moisture contained by Sec separator separation , ammonium nitrate solution under Sec pipe downstream from the liquid through the tube into the solution tank seal . In the additional amount of liquid seal cylinder gas ammonia , the solution was slightly alkaline . Under the action of vacuum , from the ammonium nitrate solution was pumped into the crystallizer tank , and stirring under vacuum action , the solution contained in the water is sucked out substantially , ammonium nitrate crystals become finished , release the door from the pan crystallizer , dried belt conveyor to the packaging, weighing from small belt after delivery by sewing machine seam , finished with the car transported to the Treasury sold.

And out into the upper portion of the evaporator and steam ( steam and a secondary reaction ), and separated by the gas-liquid separator wherein the entrained droplets of ammonia gas derived from the top of the separator , in a tangential direction into the trap , trapping of ammonium nitrate droplets have come into the trap again and in the lower part , a trap for the upper section of the steam out of the evaporator heating , gas separators to separate .

Sec waste heat steam evaporator heating with nitric acid byproduct steam boilers , Sec waste heat out of steam after the ammonia solution tank insulation and then filtered through the evaporator to the bathhouse , Sinochem , office buildings , heating or send soft pool .

One , two sections separated by the separation and crystallization of machine exhaust steam evaporated water vapor , the water jet is mixed with water into the pool .

From the acid absorption tower cooling backwater ( residual pressure 6 kg / cm 2 ) adding water evaporation and crystallization ejector for vacuum use, while cooling effect . After the water condensate and noncondensable gas mixture to the pool , using some part of the cycle to drain .

This process is characterized by :

1 , the ammonia gas preheating using waste steam , acid tank plus recovery , recycling not only the synthesis gas in the gas tank of ammonia , its effect is less than other recovery method for recovering ammonia losses, and got a high temperature dilute ammonium nitrate was significantly in favor of the reaction process .

2 , evaporating steam heating and evaporation section with the steam , Sec byproduct waste heat boiler steam Zigeiyouyu nitric acid , so that the burden for reducing the production of ammonia vapor , but also make the system stable operation .

Under 3 Sec feeding tube into the solution tank using liquid seal drum intuitive cutting, can be directly observed concentration, pH and lower material and circumstances, always find problems ; timely adjustment to ensure normal production, while allowing sampling and analysis .

4 , the tube was sealed again in the bath and is added with a reflux tube , while driving , or can produce a dilute solution of ammonium nitrate is not normal , and then return to the device and then evaporated , the job which is not only easy to operate, and to ensure normal operation and product qualification rate of crystallization of positions to provide the conditions and eliminating the ammonium nitrate solution pump .

5 , the crystallization of intermittent operation , the fault is easy to rule out , has little effect on the upper and lower positions , and easy maintenance. The crystallization vacuum plus a buffer tank to accelerate the feed , triple crystallization ability .

6 , evaporate after Sec separator for the same degree of vacuum tubes alone , evaporation and crystallization using water jet , instead of mechanical vacuum pumps and air coolers. This greatly reduces the equipment , simplifying the process and facilitate the operation , convenient maintenance , improve efficiency , reduce consumption, reduce accidents, ensure the production . And generally small plant steam supply shortages, therefore , the use of water jet pump than with steam ejector easy.